we test the limits

The machine knives are tested and optimized with regard to sharpness, cutting retention, corrosion resistance as well as concentricity to reduce noise. Taking these parameters into account and based on many years of experience, our engineers develop cutting solutions with the aim of offering

the Best-in-Class product to our customers.

Our Expertise

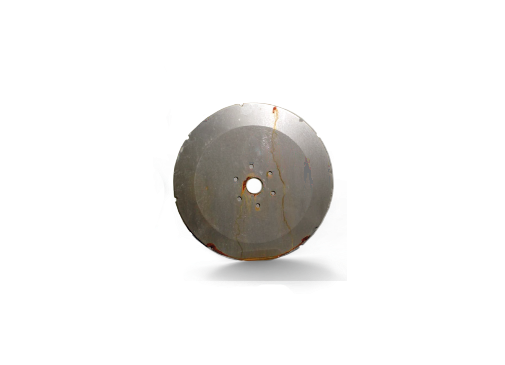

Salt Spray Test

In our salt spray test laboratory, we continuously test the corrosion resistance of our knives compared to the competition.

Hardness Testing

We continuously test the hardness of the steel to minimize the risk of knife breakage.

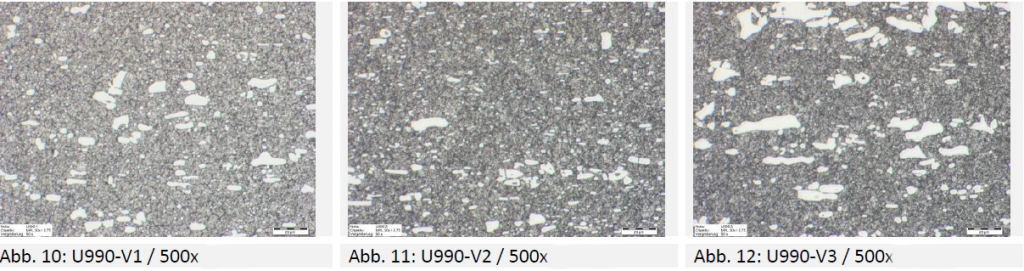

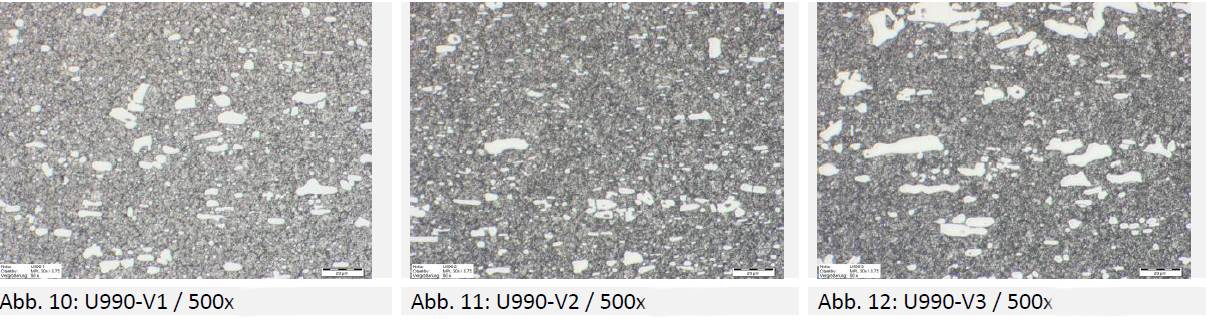

Microstructural Test

For the highest quality requirements, we perform material testing by means of metallography to qualify the heat treatment.

Salt Spray Test

Unter normierten Bedingungen werden die zu prüfenden Werkstücke in einer Prüfkammer positioniert und einer korrosionsfördernden Atmosphäre ausgesetzt. Diese wird durch das Versprühen einer Salzlösung erzeugt.

Im Technicum der ALFRED GIESSER MESSERFABRIK findet dieses Verfahren zur Qualitätssicherung von Industriemessern und Werkstücken, die in einer korrosiven Umgebung eingesetzt werden, seine Anwendung. So garantieren wir unseren Kunden eine hohe und gleichbleibende Korrosionsbeständigkeit.

Hardness Testing

Durch eine hohe Härte erhält der Stahl eine hohe mechanische sowie chemische Verschleißbeständigkeit. Jedoch nimmt bei zunehmender Härte die Zähigkeit ab, was ebenfalls eine wichtige Eigenschaft eines Industriemessers ist, um die Gefahr des Messerbruchs zu minimieren.

Um diese Eigenschaften für den Schneidprozess in ein optimales Verhältnis zu setzten, muss die Härte exakt eingestellt und der Härteprozess überwacht werden. Für eine gleichbleibende Qualität wird die Härte durch ein normiertes Härteprüfverfahren geprüft und dokumentiert.

Microstructural Analysis

A fine and homogeneous microstructure ensures a sharp cutting edge and high toughness. Metallographic microstructural testing is used to examine the quality and properties of metals after heat treatment. This is an important part of our quality assurance.

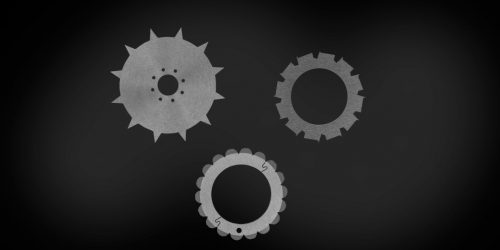

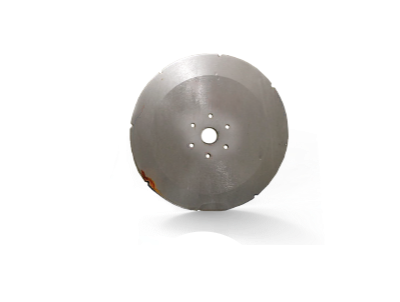

Blade Geometry

For each application, we develop the optimum geometry for the perfect cut.

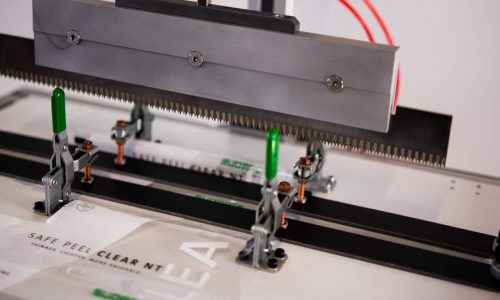

CUTTING TEST

For a precise cut, we test the best cutting solution for your specific material to be cut.

FRICTION TEST

With the help of the pin-on-disc process, we develop surfaces according to tribological aspects.

ROUGHNESS MEASUREMENT

We measure the surface quality in Rz. The roughness value has an influence on the respective cutting result.

Blade Geometry

Every material to be cut has its own individual properties, which require an adapted blade geometry. We can support you in developing the optimal geometry for the perfect cut.

Cutting test

With our cutting test bench we test your industrial knives with regard to the cutting forces and the cutting pattern. A force sensor records the occurring cutting forces in detail and allows them to be validated and optimized.

Friction Test

Friction-optimized surfaces are necessary for a gentle cut and low buildup on the knife. The friction test rig is used to determine the friction between the knife surface and the material to be cut and to optimize it from a tribological point of view.

Roughness Measurement

The surface finish is of paramount importance in the manufacture of industrial knives, especially in the medical and food industries. A low surface roughness reduces adhesion and facilitates cleaning, thus minimizing the formation of bacteria. Furthermore, the cutting performance as well as the corrosion resistance can be increased by a low roughness value (Rz). The surface roughness can be determined both tactilely and optically.

Our Expertise

Salt Spray Test

In our salt spray test laboratory, we continuously test the corrosion resistance of our knives compared to the competition.

Salt Spray Test

Unter normierten Bedingungen werden die zu prüfenden Werkstücke in einer Prüfkammer positioniert und einer korrosionsfördernden Atmosphäre ausgesetzt. Diese wird durch das Versprühen einer Salzlösung erzeugt.

Im Technicum der ALFRED GIESSER MESSERFABRIK findet dieses Verfahren zur Qualitätssicherung von Industriemessern und Werkstücken, die in einer korrosiven Umgebung eingesetzt werden, seine Anwendung. So garantieren wir unseren Kunden eine hohe und gleichbleibende Korrosionsbeständigkeit.

Hardness Testing

We continuously test the hardness of the steel to minimize the risk of knife breakage.

Hardness Testing

Durch eine hohe Härte erhält der Stahl eine hohe mechanische sowie chemische Verschleißbeständigkeit. Jedoch nimmt bei zunehmender Härte die Zähigkeit ab, was ebenfalls eine wichtige Eigenschaft eines Industriemessers ist, um die Gefahr des Messerbruchs zu minimieren.

Um diese Eigenschaften für den Schneidprozess in ein optimales Verhältnis zu setzten, muss die Härte exakt eingestellt und der Härteprozess überwacht werden. Für eine gleichbleibende Qualität wird die Härte durch ein normiertes Härteprüfverfahren geprüft und dokumentiert.

Microstructural Test

For the highest quality requirements, we perform material testing by means of metallography to qualify the heat treatment.

Microstructural Analysis

A fine and homogeneous microstructure ensures a sharp cutting edge and high toughness. Metallographic microstructural testing is used to examine the quality and properties of metals after heat treatment. This is an important part of our quality assurance.

Blade Geometry

For each application, we develop the optimum geometry for the perfect cut.

Blade Geometry

Every material to be cut has its own individual properties, which require an adapted blade geometry. We can support you in developing the optimal geometry for the perfect cut.

CUTTING TEST

For a precise cut, we test the best cutting solution for your specific material to be cut.

Cutting test

With our cutting test bench we test your industrial knives with regard to the cutting forces and the cutting pattern. A force sensor records the occurring cutting forces in detail and allows them to be validated and optimized.

FRICTION TEST

With the help of the pin-on-disc process, we develop surfaces according to tribological aspects.

Friction Test

Friction-optimized surfaces are necessary for a gentle cut and low buildup on the knife. The friction test rig is used to determine the friction between the knife surface and the material to be cut and to optimize it from a tribological point of view.

ROUGHNESS MEASUREMENT

We measure the surface quality in Rz. The roughness value has an influence on the respective cutting result.

Roughness Measurement

The surface finish is of paramount importance in the manufacture of industrial knives, especially in the medical and food industries. A low surface roughness reduces adhesion and facilitates cleaning, thus minimizing the formation of bacteria. Furthermore, the cutting performance as well as the corrosion resistance can be increased by a low roughness value (Rz). The surface roughness can be determined both tactilely and optically.

Our Competences

Developing

We develop and explore new techniques as well as approaches to not only remain relevant in the field of industrial cutting, but also to expand our product portfolio and services.

Testing

We test different solutions through our testing equipment in order to develop optimal solutions for our customers.

reporting

In connection with competitive product analyses, we provide maximum transparency. We share the results with our customers.

Our experts will be happy to help you

Contact form

Forschungspartner, mit denen wir zusammenarbeiten.

Forschungspartner, mit denen wir zusammenarbeiten.