Numerous machine manufacturers, who are often world market leaders in their field of application, appreciate the professional and binding cooperation with ALFRED GIESSER MESSERFABRIK. This is how we live partnerships with our customers that have lasted for over 100 years. This is a novelty in today's world, but also evidence of the fact that we do not stand still but continuously work on providing our customers with innovative and qualitatively best solutions.

Because only in this way they can convince in the competition

and gain market share.

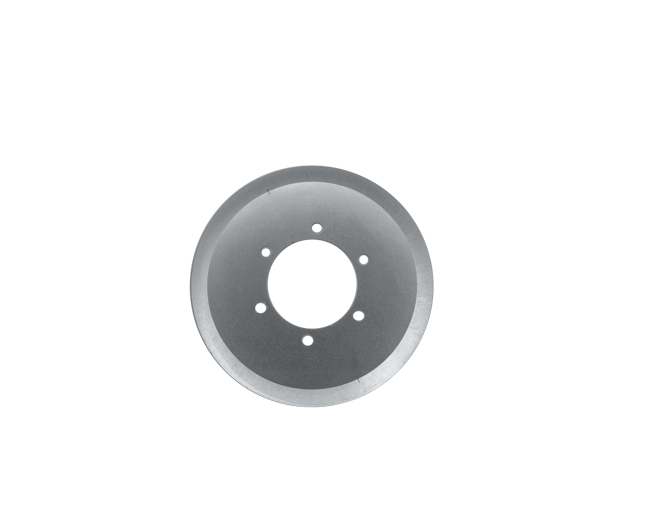

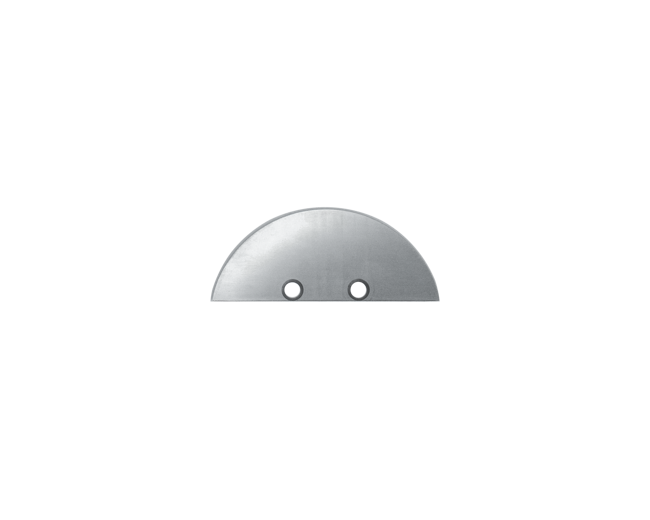

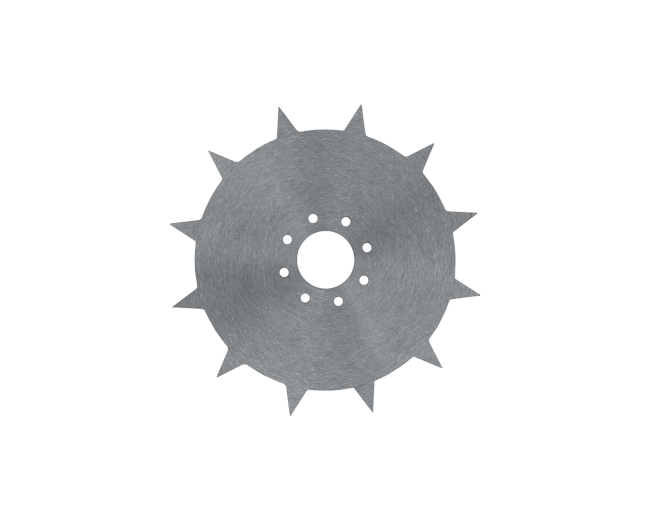

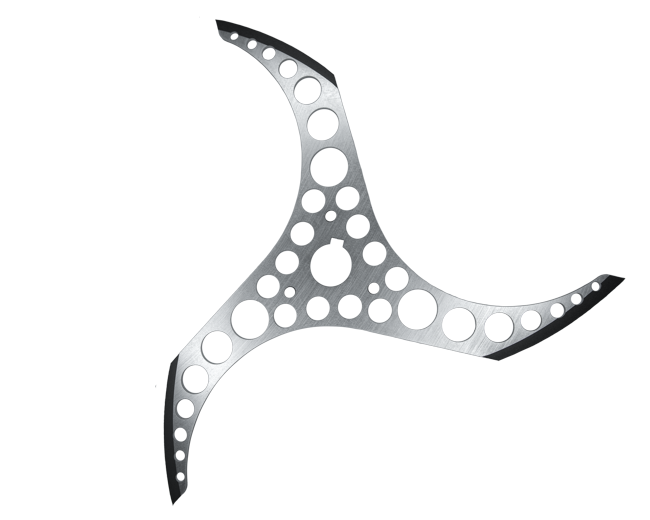

Knife design for a perfect cut

Every industry and every company that we serve has individual requirements for its cutting processes. ALFRED GIESSER ENGINEERING has set itself the goal of always meeting these different circumstances in the best possible way.

Listen ‒ Advise ‒ Implement

The first step is analyzing the task and the production processes. Our experienced specialists ask the right questions and listen carefully. In close coordination with the customer, a project-related offer is prepared according to the customer's needs.

Due to the high vertical range of manufacture and the modern machinery, ALFRED GIESSER MESSERFABRIK guarantees best quality and fast delivery times compared to the competition.

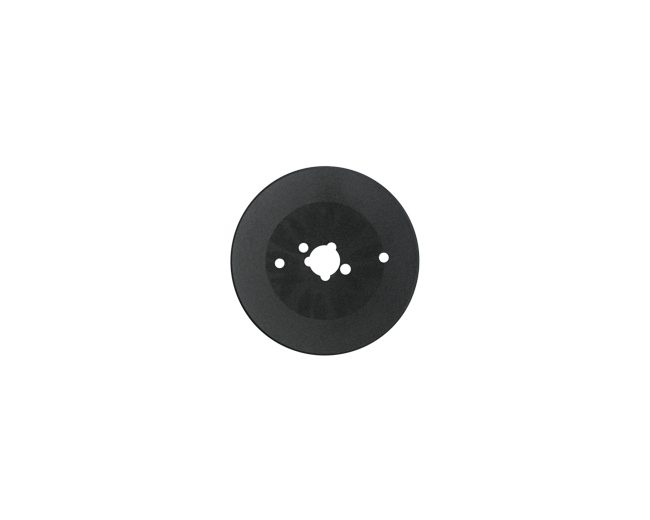

Materials

- Hardenable corrosion resistant tool steels

- High-alloy tool steels

- High Speed Steel (HSS)

- Powder Metallurgical Steels (PM)

- Cemented carbide

- High performance ceramics

With our modern machinery, we are able to manufacture a wide variety of product solutions.

Hardness

- Through hardening

- Edge hardening

- Surface hardening

- Deep-freezing

In our innovative hardening centre, we are able to execute various heat treatment processes for specific requirements.

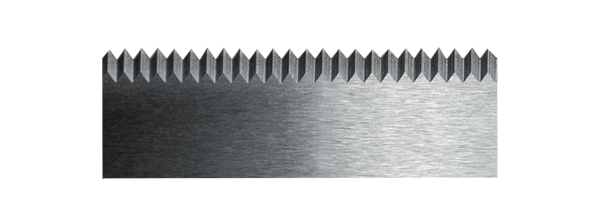

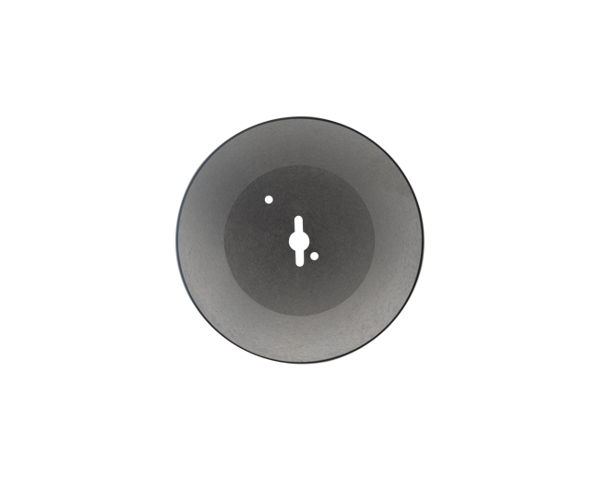

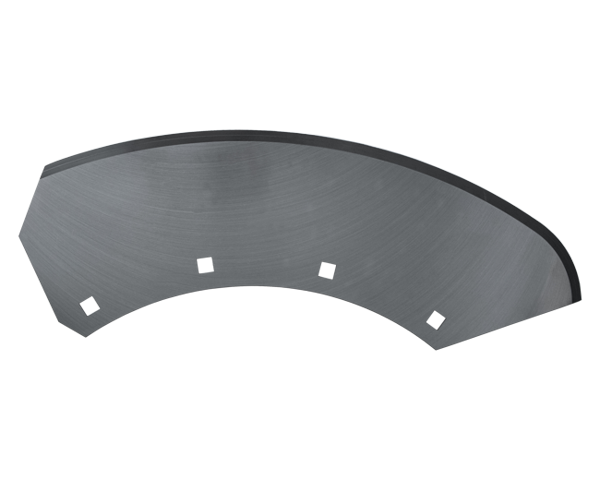

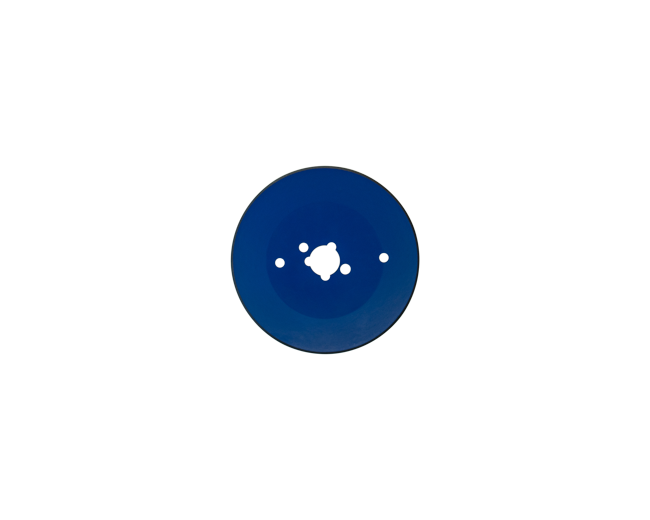

Blade Geomtery

- One-sided or two-sided main chamfer

- Radius chamfer

- Pre-bevel

- Counter chamfer

- Offset chamfers

- Toothed blade

- Laser cut, eroded or polished profiles

- Straight, curved or diagonal bevels

- 90° cutting edges with clearance angle

With our modern machinery, we are able to manufacture a wide variety of product solutions.

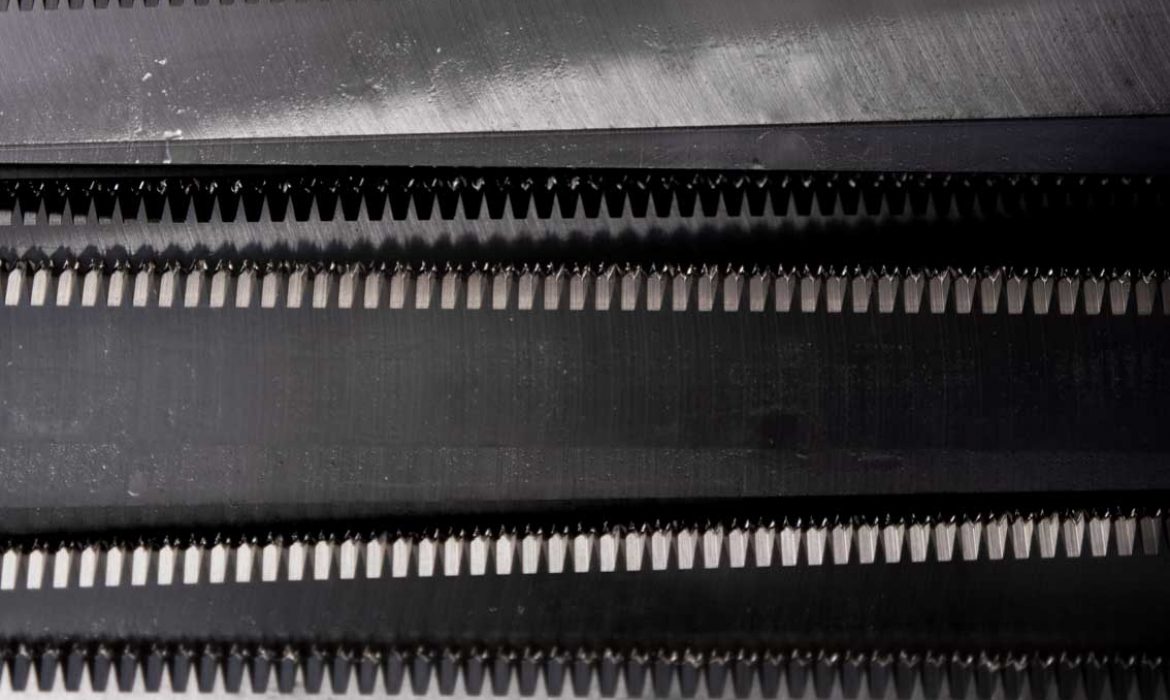

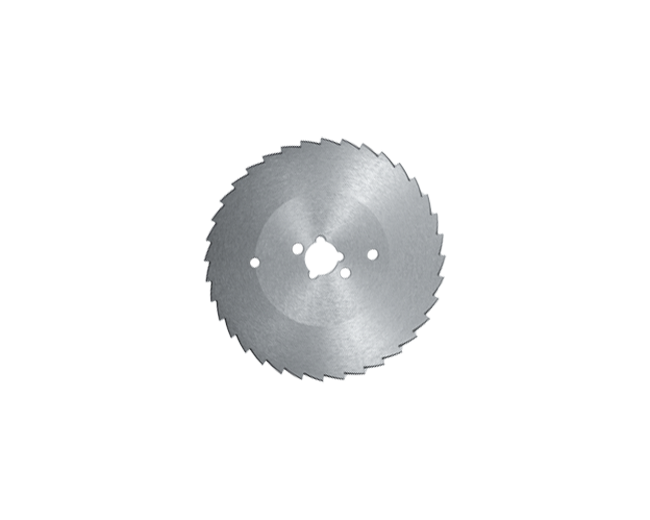

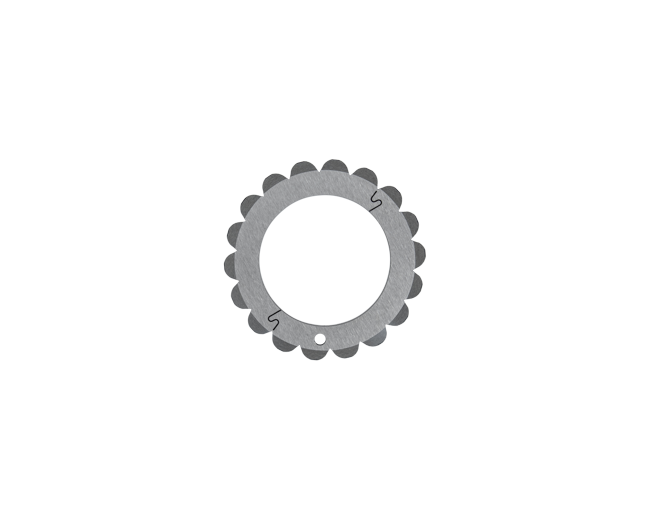

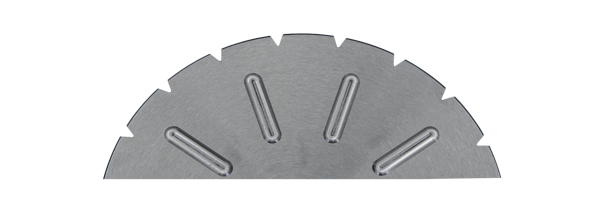

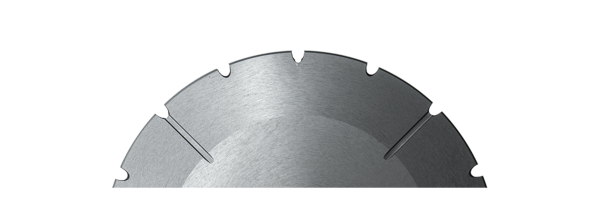

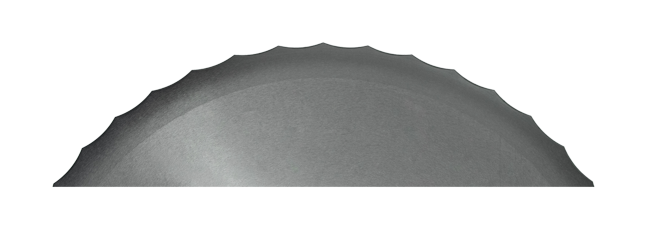

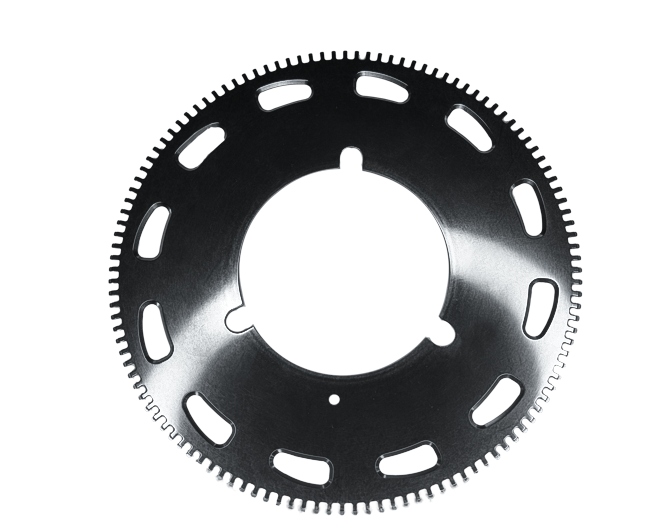

Toothing

- Toothing

- Microserration

- Indented gearing

- Schaft gearing

- Slots gearing

- Groove gearing

- Special gearing

With our modern machinery, we are able to manufacture a wide variety of product solutions.

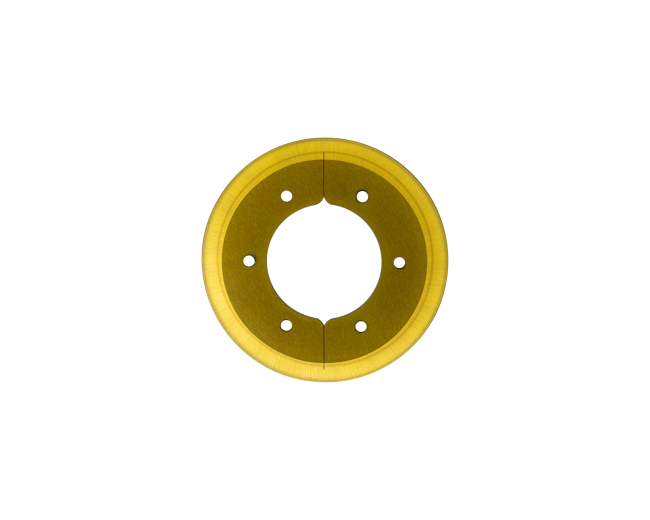

Surface

- Grinded

- Polished

- Electro-Polished

- Lapping

- Trowalized

- Vibratory finishing

With our modern machinery, we are able to manufacture a wide variety of product solutions.

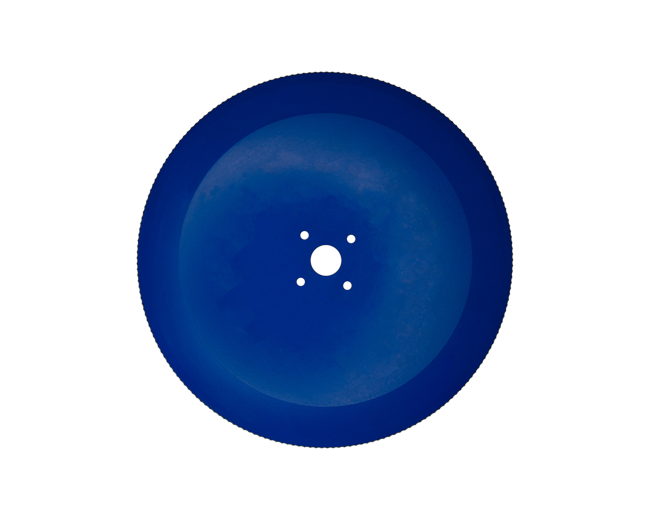

Coating

- PTFE

- Hard chrom

- TiN

- TiCN

- Teflon

With our modern machinery, we are able to manufacture a wide variety of product solutions.